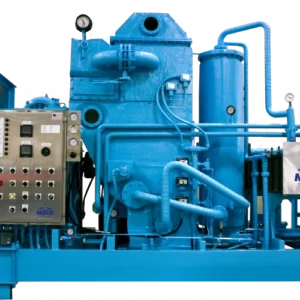

MECO waste heat distillers have been a workhorse in the for over 60 years. They are commonly used on drilling rigs and offshore platforms, and in shipboard and industrial applications. MECO waste heat distillers are available in single-stage and two-stage configurations for reduced load applications. The MECO waste heat distillers are supported by MECO 24-hour customer service.

Technical Data

| MODEL |

CAPACITY in GPD [m3/day] |

| MPD3 |

530–1,321 [2-5] |

| MPD7 |

1,850–3,170 [7-12] |

| MPD13 |

2,642–6,605 [10-25] |

| MPD23 |

7,925–9,250 [30-35] |

| MPD35 |

10,568–15,850 [40-60] |

| MPD45 |

18,500–26,420 [70-100] |

Overview

- Leading manufacturer of waste heat desalination plants for 60 years

- Produces potable drinking water and high-quality distilled water

- Completely packaged units for minimum field installation

- with surface preparation and coatings suitable for marine environment

- Hazardous area classification options

- Offers both plate-type and tubular-type evaporators

-

- Offers custom system designs

-

- Backed by warranty

Standard Features

- Evaporators available in single-stage and two-stage configurations for reduced load applications

- Simple operation utilizing a single brine eductor, distillate pump and control panel

- MECO Plate Distillers – “MPD” units have titanium plates and stainless steel evaporator shell

- Unique plate design specifically for distillers enables cleaning without removing plates & variations of capacity with the addition of plates

- Ease of access and maintenance with removable evaporator head

- Corrosion resistant materials, including:

- 90/10 copper nickel

- Titanium

- Inconel

- Monel

Equipment Details

- Galvanized rigid steel conduit

- Stainless steel airlines

- Integrated control and instrument panel

- TEFC motors