GENERAL SPECIFICATIONS:

- 9HP Electric motor capacity of the oil cleaning water recovery system

- Automatic Pump Out and Wash Water Recycle System with 3000 W Generator

- 2-inch vacuum hose reel, 200 feet (60.96 m)

- Stainless steel fresh water tank combined with high pressure hose reel

- Weight of the system 1814 kg

DETAIL SPECIFICATIONS:

- Hot or Cold Water Pressure Washer

- 18 l/min ± 1% @ 3500 PSI (or two guns each operating at 9.46 l/min @ 3500psi)

- Kohler 624cc Electric Start Engine

- Belt drive Tri-plex oil bath general pump

- 3600psi safety relief

- Flow Actuated unloader Standard – Optional Pressure Trapping unloader allows single or dual gun operation

- Unloader return / bypass hose routed back to holding tank

- 2900 Watt 120V generator for burner system

- On-Board Anti-Freeze Holding Tank (plumbed into system inlet w/ ball valve shutoff manifold for ease of winterization)

- Stacked Stainless Steel Fresh Water Inlet Hose & High Pressure Matched Hose Reels

- 200’ (60.96 m) R2 wire 5800psi high pressure hose

- Four quick connect nozzles

- 225 Gallon (851.7 liter) Water tank plumbed with a 2″ Clean Out Dump valve for quick draining

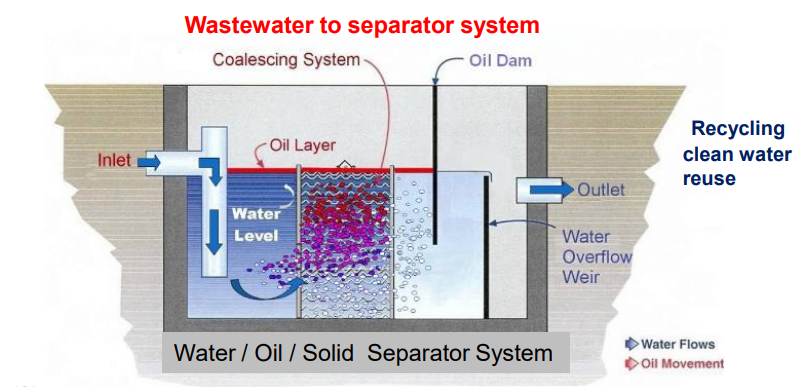

RECYCLING SYSTEM:

- Reusable oil filtering foam media

- Oleophilic (oil attracting) coalescing plates

- Oil absorption skimmer media

- Automatic Discharge Pump System

- Stepped reduction polishing filter system – 75, 50, 25 to 5 Micron

- Recycling rate of up to 11 gallons (41.6 liter) per minute

- System design allows for optimum settling time

- 16″ Clean & Capture Tool Surface Cleaner

- 5′ Vacu-Boom

- 3 – 5′ Sand Snake Berms / Drain Dikes

RECOVERY VACUUM:

- 235 cfm (399 m3/hour) of air lift

- 55 gallon (208 litter) Removable heavy solids Separation

- Automatic discharge pump out

- 200’ (60.96 m) heavy duty crush resistant suction hose

- 1 1/2″ Clean Out Drain Valve

TRAILER SPECIFICATIONS:

- Tandem axle 3500lb (1587 kg) per axle

- Dimensions: 6′ (1.82 m) wide X 13′ (3.96 m) length

WARRANTY INFORMATION:

- 5 Year coil warranty

- 7 Year back end pump warranty

- Lifetime warranty on head

- 90 Day warranty on wear parts

- 1 year labor warranty

SYSTEM TYPE:

Hot & Cold Water, high pressure, gas powered, skid pressure washer. Unit has appropriate fully automatic safety controls.

GENERAL SPECIFICATIONS:

Discharge 4.7 GPM (17.78 l/min)

Pressure 3500 PSI

Gas Engine 624CC

HIGH PRESSURE HOSES:

3/8” ID double steel braid type exceeding SAE100R2 performance specifications. Equipped with a swivel and safety protection bend restricting collars. Rated Rated at 5800 PSI at 250° F.

TRIGGER GUNS:

Insulated pistol type safety shut off gun supplied shall be rated at 10 gpm, 5000 psi, and 300° F. Constructed from Fiberglass – reinforced polyester with brass and stainless steel valves and seats.

WANDS:

A 48” dual lance wand with insulated grab handle on wand for operator protection.

WAND HOLDER:

Exclusive Rugged Gear secure wand holder

NOZZLES:

Appropriate high pressure nozzles for single gun operation shall be supplied in 0° 15° 25° & 40° flat spray pattern. The nozzles shall be of a through hardened 420 stainless steel material with an interlock coupler nipple made of annealed 303 stainless steel with 80 Rockwell hardness rating.

DRIVES:

Belt drive system with cast iron bushed bore pulley, grip notch V-section size B belts, and adjustment plate for proper belt tension and alignment. All belts to be covered by safety machine cover.

HIGH PRESSURE PUMP:

Triplex, Ceramic plunger, oil bath crankcase type with forged brass head, mounted on a vibration isolation deck. Pump bypass loop shall be equipped with 145° thermal relief valve.

UNLOADER VALVE:

The pressure washer shall be equipped with a EITHER a flow actuated or pressure trapped unloader valve suitable for dual gun operation rated for a minimum of 8 gpm at 3900 psi.

FRAME:

Unit protected by a heavy square tube steel frame. Components to be located for ample service/inspection accessibility. All painted material will be painted with a “Hammerite” Powder Coated finish.

CONTROLS:

Unit has a control panel with the following:

Burner Switch

Vinyl operating instructions and safety information in English and Spanish, attached by a high strength waterproof adhesive.

HOSE QUICK CONNECTIONS:

Quick couple connectors with stainless steel retainer ring & support balls.

BURNER ASSEMBLY:

Heating Chamber is a continuous heating coil type, diesel fired. Fuel solenoid & solid state ignition system.

RECOVERY VACUUM:

- 235 cfm (399 m3/hour) of air lift

- 55 gallon (208 litter) Removable heavy solids Separation

- Automatic discharge pump out

- 200’ (60.96 m) heavy duty crush resistant suction hose

- 1 1/2″ Clean Out Drain Valve

TRAILER SPECIFICATIONS:

- Tandem axle 3500lb (1587 kg) per axle

- Dimensions: 6′ (1.82 m) wide X 13′ (3.96 m) length

WARRANTY INFORMATION:

- 5 Year coil warranty

- 7 Year back end pump warranty

- Lifetime warranty on head

- 90 Day warranty on wear parts

- 1 year labor warranty

SYSTEM TYPE:

Hot & Cold Water, high pressure, gas powered, skid pressure washer. Unit has appropriate fully automatic safety controls.

GENERAL SPECIFICATIONS:

Discharge 4.7 GPM (17.78 l/min)

Pressure 3500 PSI

Gas Engine 624CC

HIGH PRESSURE HOSES:

3/8” ID double steel braid type exceeding SAE100R2 performance specifications. Equipped with a swivel and safety protection bend restricting collars. Rated Rated at 5800 PSI at 250° F.

TRIGGER GUNS:

Insulated pistol type safety shut off gun supplied shall be rated at 10 gpm, 5000 psi, and 300° F. Constructed from Fiberglass – reinforced polyester with brass and stainless steel valves and seats.

WANDS:

A 48” dual lance wand with insulated grab handle on wand for operator protection.

WAND HOLDER:

Exclusive Rugged Gear secure wand holder

NOZZLES:

Appropriate high pressure nozzles for single gun operation shall be supplied in 0° 15° 25° & 40° flat spray pattern. The nozzles shall be of a through hardened 420 stainless steel material with an interlock coupler nipple made of annealed 303 stainless steel with 80 Rockwell hardness rating.

DRIVES:

Belt drive system with cast iron bushed bore pulley, grip notch V-section size B belts, and adjustment plate for proper belt tension and alignment. All belts to be covered by safety machine cover.

HIGH PRESSURE PUMP:

Triplex, Ceramic plunger, oil bath crankcase type with forged brass head, mounted on a vibration isolation deck. Pump bypass loop shall be equipped with 145° thermal relief valve.

UNLOADER VALVE:

The pressure washer shall be equipped with a EITHER a flow actuated or pressure trapped unloader valve suitable for dual gun operation rated for a minimum of 8 gpm at 3900 psi.

FRAME:

Unit protected by a heavy square tube steel frame. Components to be located for ample service/inspection accessibility. All painted material will be painted with a “Hammerite” Powder Coated finish.

CONTROLS:

Unit has a control panel with the following:

Burner Switch

Vinyl operating instructions and safety information in English and Spanish, attached by a high strength waterproof adhesive.

HOSE QUICK CONNECTIONS:

Quick couple connectors with stainless steel retainer ring & support balls.

BURNER ASSEMBLY:

Heating Chamber is a continuous heating coil type, diesel fired. Fuel solenoid & solid state ignition system.

HEATING COIL:

High test ASTM A53 Schedule 80 spiral helix wound coil, with a material thickness of .140 in., pipe dimension .854 od. Coil contains hot gas baffling for unparalleled coil efficiency. Welding done to ASME standards. The heating coil shall be insulated with a fiberfrax ceramic blanket, # 6 density, 1 in. thick. The entire coil will be surrounded our exclusive cold coil wrap.

SAFETY RELIEF VALVE:

A high pressure safety relief valve shall be installed as a secondary safety device in the event an over pressurization condition occurs. This device shall be located at the outlet of the pump and shall be set at 3900 psi.

SAFETY FLOW SWITCH:

Shall be located on cold water side to prevent thermal damage. This safety switch will be hermetically sealed to prevent moisture damage.

High test ASTM A53 Schedule 80 spiral helix wound coil, with a material thickness of .140 in., pipe dimension .854 od. Coil contains hot gas baffling for unparalleled coil efficiency. Welding done to ASME standards. The heating coil shall be insulated with a fiberfrax ceramic blanket, # 6 density, 1 in. thick. The entire coil will be surrounded our exclusive cold coil wrap.

SAFETY RELIEF VALVE:

A high pressure safety relief valve shall be installed as a secondary safety device in the event an over pressurization condition occurs. This device shall be located at the outlet of the pump and shall be set at 3900 psi.

SAFETY FLOW SWITCH:

Shall be located on cold water side to prevent thermal damage. This safety switch will be hermetically sealed to prevent moisture damage.