for the desalination of saltwater. Since then, we’ve refined and improved the technology to deliver high-quality potable drinking water and distilled water in some of the . And since MECO has installations worldwide, you have access to a global service network that can respond quickly to emergencies and service maintenance needs.

Technical Data

| MODEL |

CAPACITY in GPH [m3/hr] |

| PEE2100M3C |

2,100 [8] |

| PEE2750M3C |

2,750 [10] |

| PEE5500M3C |

5,500 [21] |

| PEE6600M3C |

6,600 [25] |

| PEE7500M3C |

7,500 [28] |

| PEE10000M3C |

10,000 [38] |

| PEE15000M3C |

15,000 [57] |

| PEE20000M3C |

20,000 [76] |

Notes: Capacities are based on seawater with a TDS of 35,000 ppm at 77°F (25°C). MECO M3C units typically operate based on a concentration ratio of 1.77.

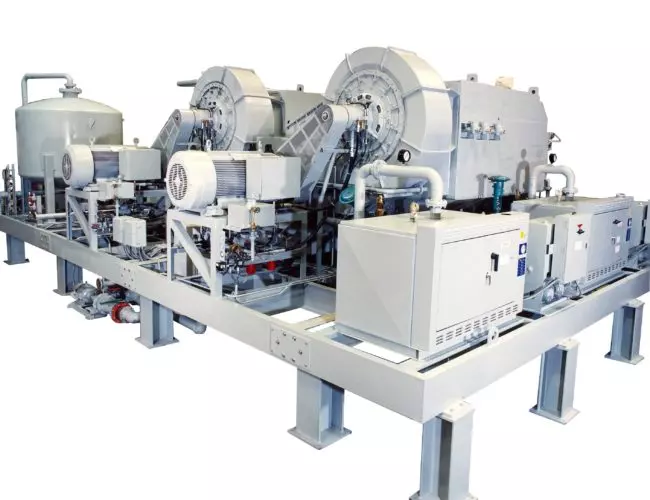

Overview

- Leading manufacturer of vapor compression desalination plants

- Produces potable drinking water and high-quality distilled water

- Completely packaged units for minimum field installation

- Superior energy efficiency

- Offers the largest vapor compression still available capacity of 20,000 gallons per hour

- All components manufactured by MECO

-

-

- Backed by warranty

Standard Features

- Vertical natural circulation evaporator

- Feedwater quality tolerance

- Scale effects reduced

- No pumps or spray nozzles

- Straight annealed tubes in evaporator

- Individual tubes can be replaced as opposed to replacing the entire tube bundle

- No residual stresses or surface finish problems commonly found with U-tubes

- Deaeration of feedwater

- Non-condensibles removed prior to distillation

- Corrosion reduction

- Corrosion resistant materials

- 90/10 copper nickel

- Titanium

- Inconel

- Monel

Equipment Details

Galvanized rigid steel conduit

- Stainless steel airlines

- Integrated control and instrument panel

- TEFC motors

MECO Vapor Compressor

- Manufactured by MECO

- Immediate spare parts availability

- Exchange program

- Inconel impeller and Monel-process contact components

- New Lube Lock Sealing System

- Directly mounted with no vapor ductwork

- Space friendly

-

- Easy access for maintenance