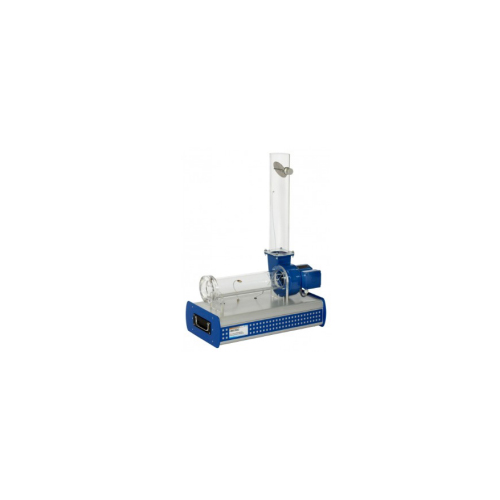

AHM280 Experiments With A Radial Fan Didactic Equipment Thermal Experiment Equipment

- Description

- Radial fans are used to transport gases with non-excessive pressure differences. The medium is drawn in axially to the drive shaft of the radial fan and is deflected by 90° by the rotation of the rotor and discharged radially.

- The experimental unit provides the basic experiments to get to know the operating behaviour and the most important characteristic variables of radial fans.

- HM 280 features a radial fan with variable speed via a frequency converter, an intake pipe and a delivery pipe. The transparent intake pipe is fitted with guide plates for flow guidance and with a flow straightener to calm the air. This enables precise measurements even with heavily reduced operation. The air flow is adjusted by a throttle valve at the end of the delivery pipe.

- To demonstrate the effect of different blade shapes two rotors are included in the scope of delivery: one rotor with forward curved blades and one with backward curved blades. The rotors are easily interchangeable.

- The experimental unit is fitted with sensors for pressure and temperature. The flow rate is determinated via differential pressure measurement on the intake nozzle. The microprocessor-based measuring technique is well protected in the housing. The measured values are transmitted directly to a PC via USB where they can be analysed using the software included.

- All the advantages of software-supported experiments with operation and evaluation are offered by thsoftware and the microprocessor.

- Specification

- functioning and operating behaviour of a radial fan

- radial fan with 3-phase AC motor

- variable speed via frequency converter

- transparent intake and delivery pipes

- throttle valve to adjust the air flow in the delivery pipe

- interchangeable rotors: 1 rotor with forward curved blades and 1 rotor with backward curved blades

- determination of flow rate via intake nozzle

- display of differential pressure, flow rate, speed, electrical power consumption and hydraulical power output, temperature and efficiency

- due to integrated microprocessor-based instrumentation no additional devices with error-prone wiring are required

- display and evaluation of the measured values as well as operation of the unit via software

- software with control functions and data acquisition via USBunder Windows 8.1, 10

- Technical data

- Intake pipe

- inner diameter: 90mm

- length: 430mm

- Delivery pipe

- inner diameter: 100mm

- length: 530mm

- Radial fan

- power consumption: 110W

- nominal speed: 2800min-1

- volumetric flow rate: 480m3/h

- pressure difference: 300Pa

- Measuring ranges

- differential pressure: 0…1800Pa

- flow rate: 0…1000m3/h

- temperature: 0…100°C

- speed: 0…3300min-1

- power consumption: 0…250W

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase; 120V, 60Hz, 1 phase

UL/CSA optional

- Dimensions and weight

- LxWxH: 670x340x940mm

Weight: approx. 20kg