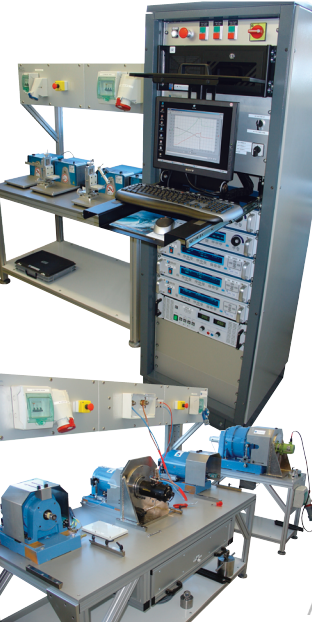

CUSTOMIZED TEST SYSTEM FOR AIRCRAFT MOTORS

APPLICATION

This

Customized Motor Test System is designed to test a wide range of electrical

motors used on passenger aircraft. Motors to be tested include: flap regulator

motors, hydraulic pressure regulator motors and air-cooling motors.

With

three dynamometer benches, the system enables the user to test motors from 18

mN·m / 7 W to 600 N·m / 24 kW, with speeds up to 30,000 rpm. All three ANAXI

dynamometer technologies are employed— hysteresis, Eddy-current and magnetic

powder—and are utilized depending on the torque versus-speed range of the

motor(s) to be tested.

COMPONENTS

•

Heavy-Duty Equipment Rack: for housing all integrated electronics

•

Three Custom Dynamometer Benches: with noise damping, electrical interlocking

and accessible connector panels

•

Fan Testing Bench: for measuring raw speed output of aircraft fan motors

•

Three Eddy-Current Dynamometers (with 600-bit speed pickup): one 2WB 65 and two

2WB 115

•

Four Hysteresis Dynamometers: HD-100, HD-400, HD-505 and HD-510 • One Magnetic

Powder Dynamometer: 1PB 115

•

Two DSP6001 High-Speed Programmable Dynamometer Controllers

•

M-TEST 4.0 Motor Testing Software: adapted to accommodate multiple power

supplies

•

Two 6510e Single-Phase Power Analyzers

•

One 6530 Three-Phase Power Analyzer

•

Custom Motor Fixtures

•

Safety Guards

•

AC & DC Power Supplies (12 kW, 45 kW and 60 kW)

•

PC, 17” Monitor and Keyboard

CUSTOM BENCHES & FIXTURES

Fixtures

designed for this system are used to secure the motors in place during a test

but they also allow motors to be easily moved from one dynamometer to another

for assorted tests. Accessible connector panels, located on each dynamometer

test bench, allow for the quick connection of motors when setting up a test.

Both features highlight the system’s excellent flexibility and efficiency