TB-220726-V-209 Vapour Jet Compressor Training System Didactic Equipment Thermal Transfer Demonstrational Equipment

The System Should cover the following Training Objective:

Familiarization with compression refrigeration systems based on the vapour jet method

Investigation of clockwise and anticlockwise Rankine cycle

Investigation of energy balances

calculation of the coefficient of performance of the refrigeration circuit

Familiarization with thermodynamic cycle in the log p-h diagram

Investigation of operating behaviour under load

Familiarization with solar thermal vapour jet refrigeration

Practice of solar heat for cold production

Components of solar refrigerating plants according to the vapour jet method

Operation of a vapor jet compressor on a solar thermal flat collector

Optimization of the operating point

Extended concept on the use of thermal solar plants

Energy management for solar thermal cooling systems

Investigation of the functions of the flat collector and the solar circuit

Acquiring the net power

Investigation of relationship between flow and net power

Acquiring the collector efficiency

Investigation of relationship between temperature difference (collector/environment) and collector efficiency

The System comprising the following:

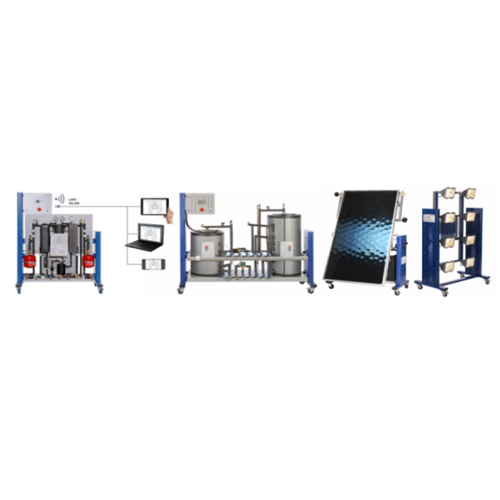

1. Vapour Jet Compressor Unit

Minimum Technical Specifications Required (like or better than):

The system is placed on a rigid frame of four castor wheels

Refrigeration circuit with condenser, evaporator and vapour jet compressor of 1,7mm min. diameter of convergent-divergent nozzle and 7mm min. diameter of mixing jet for refrigerant

Vapour circuit with pump and vapour generator for operating the vapour jet compressor

Transparent tank: 3.5L with water-cooled pipe coil of area: 0.17m2 as condenser

Transparent tank: 3.5L with adjustable heater as an evaporator of power: 4x 125W

Flooded evaporator with float valve as expansion element

Vapour generator with electrically heated water jacket

Vapour generator refrigerant tank of 0.75L, 9L water jacket, 2kW heater power

Pump of maximum flow rate:1,7L/min and maximum head: 70mWS

Flow meter to measure flow rate (cooling water) of range 0 to 1.5

2x pressure sensors of range 0 to 10bar and another 2x of range -1 to 9bar

12x temperature sensors of range -20 to 100°C

Power measuring range: 0 to 750W and 0 to 3kW

Data acquisition software

USB interface

PC Core i7, DVD+/-RW, 8GB RAM, 1TB Hard Disk Drive, Optical Mouse, Multimedia Keyboard, Monitor (21″) LED

2. Solar Heat Supply Unit

Minimum Technical Specifications Required (like or better than):

feed line to the vapour generator with temperature and flow rate measurement

return line with temperature measurement

measured values transferred to Vapor Jet Compressor Unit for further processing in the software

Pump with power consumption: 40Wm max. flow rate: 1m3/h and head: 4,8m

Temperature measuring ranges: 2x 0 ~ 120 °C

flow rate measuring range: 10 ~ 300 L/h

3. Domestic Water Heating Unit

Minimum Technical Specifications Required (like or better than):

The system is placed on a rigid frame of four castor wheels

Selectively absorbing coating solar thermal flat collector

Adjustable collector tilt angle

Solar circulation station with pump, expansion vessel and safety valve (4bar)

Hot water circuit (of absorbing surface: 2.3m2, rated throughput: 20 to 200L/h and operating pressure: 1 to 3bar) with buffer tank (of capacity: 70L), pump and plate heat exchanger (of 3kW, 10 plates)

4x bimetallic thermometers: 0 to 120°C

Solar controller with temperature, flow and illuminance sensors

Data logger and SD memory card

Flow rate sensor measuring range varies from 20 to 300L/h

Artificial Light Source Unit 8 KW