ASS203 Compression Refrigeration Trainer Didactic Eqiupment

Description

The setup of represents a typical refrigeration circuit consisting of a hermetic compressor, condenser, evaporator and expansion element. Evaporator and condenser are designed as finned tube heat exchangers. The pipes of both heat exchangers are partially transparent to visualise the process of the phase transition during evaporation and condensing. Three capillary tubes of different lengths and a thermostatic expansion valve can be compared as expansion elements.

The trainer is equipped with a receiver for refrigerant. Using the receiver, refrigerant can be added to or removed from the refrigeration circuit. This allows for the effects of overfilling or underfilling of the system to be examined.

The flow rate of the refrigerant is read from a flow meter. Temperature and pressure in the refrigeration circuit and the electrical power consumption of the compressor are recorded by sensors. The measured values can be read on digital displays. At the same time, the measured values can also be transmitted directly to a PC via USB.

The data acquisition software is included. Parameter changes in the refrigeration circuit can be viewed dynamically in the software’s log p-h diagram.

Specification

investigation of a refrigeration system with different expansion elements

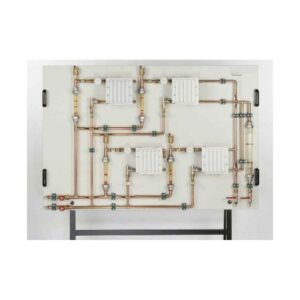

refrigeration circuit consisting of a hermetic compressor, condenser, evaporator and expansion element

transparent finned tube heat exchangers as condenser and evaporator to observe the phase transitions of the refrigerant

expansion valve and capillary tubes of different lengths as expansion elements

receiver for underfilling/overfilling the system with refrigerant

sensors record pressure, temperature and flow rate

compressor equipped with two pressure switches

software for data acquisition via USB under Windows 10

Technical data

Compressor

power consumption: 288W at 7,2°/54,4°C

refrigeration capacity: 463W at 7,2/54,4°C

Condenser and evaporator with fan

max. volumetric air flow rate condenser: 300m3/h

max. volumetric air flow rate evaporator: 180m3/h

Capillary tubes: 1,5m, 3m, 6m

Receiver for refrigerant: 1,3L

Refrigerant

AR134A

filling volume: 2,5kg

ACO2-equivalent: 1,6t

Measuring ranges

pressure: -1…9bar / -1…24bar

temperature: 4x -40…150°C, 1x -100…100°C

mass flow rate: refrigerant, calculated 2…19kg/h

power consumption: 0…1000W

230V, 50Hz, 1 phase

230V, 60Hz, 1 phase

120V, 60Hz, 1 phase